WELCOME TO WWG ENGINEERING PTE. LTD.

Singapore Largest Integrated Complete One-Stop Engineering Services and Solutions Provider

At WWG Engineering Pte Ltd, we pride ourselves as Singapore's Thermal Spraying Coating, Advance Laser Cladding, Mechanical, Electrical, Electronics Instrumentations and Engineering Equipment Specialists. We are offering 24-Hour Round-The-Clock Services to the industry.

WWG Engineering Pte Ltd is certified under ISO 9001, 14001, 45001 and BizSAFE Star. "UHLA" is WWG Engineering's proprietary Ultra High Speed Laser Cladding Technology Registered Trademark.

WWG's technology development roadmap has a very clear objective. WWG's mission is to continue assembling some of the most sought-after technologies surrounding and relating to our core engineering services, all under one roof. Automation, CNC Machines, Multi-axis Robotic Arms, Coordinate Measurement Machine (CMM) and Heat Treatment facilities are effectively deployed in WWG businesses. By doing this, we are able to establish a seamless matching of Surface Engineering Modification Technology with Mechanical Engineering Equipment Repair, Refurbishment, Parts Re-manufacturing and Services Solutions, further complementing by Electrical, Electronics and Instrumentations Services.

Surface Engineering Modification Technologies and Mechanical Engineering Services can be performed In-house and on-site/in-situ. These include Thermal (Metal) Spray, Rokide Ceramic coating, Plasma Spraying, HVOF coating, COLD Spray Coating, UHLA Ultra High Speed Laser Cladding, Hard Chrome/Nickel Plating, Anti-Corrosion Protective coating (Blasing-Painting, Class-Flakes Ceramics Epoxy Coating, TSA, TSZ, lnconel etc.), Babbit (White Metal) Re-metaling, Specialized Welding Including Cast Iron (with approved WPS, PQR), Workshop Machining Turning, CNC Milling, CNC Lathe, CNC Horizontal Boring, Cylindrical, Surface, Crankshaft Grinding, In-situ machining, Line-boring, On-site Milling, Flange Facing, Pipes Cold-Cutting, Laser Alignment, all mechanical equipment and machinery dismantling, troubleshooting, Overhaul, Repair, Dynamic Balancing Re-assembly, Testing, necessary 3rd Party Quality and Marine Class Approval.

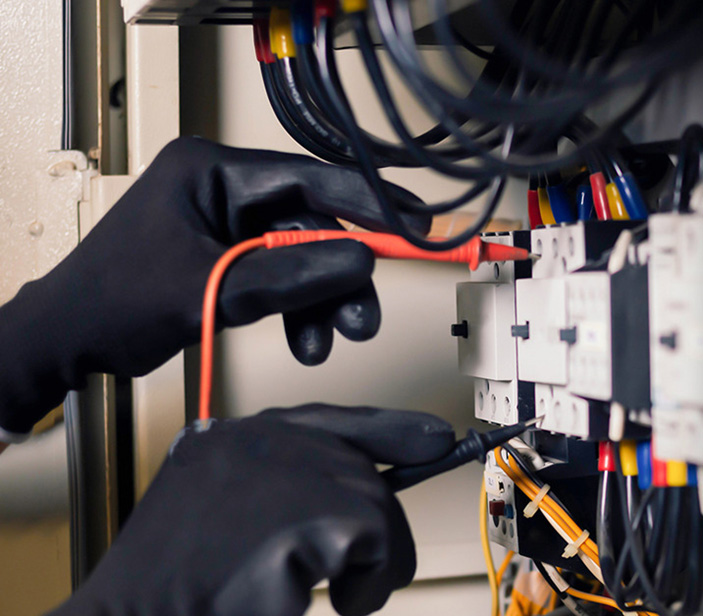

As an industrial powerhouse for driving an Integrated, Complete One-Stop Engineering Services and Solutions, Electrical, Electronics and Instrumentations Services are among the latest series of WWG Engineering's technological offerings. Such services include Diesel Generators, CNC and Factory Machineries Maintenance, Equipment Troubleshooting, Installations, Panel Design and Services, Cable Glanding and Termination on Rigs, Vessels, and Oil & Gas Facilities.

As a complementing business activity, WWG Is a distributor to Kennametal's Stellite and Carbides range of welding rods, powders, carbide inserts and a service partner to refurbish Industrial Die Plates. WWG ls also in partnership with Osborne Engineering In White Metal Bearings repair, re-metaling, new White Metal Bearing remanufacturing and a series of Osborne Business Solutions.

Established in January 2012, WWG Engineering Pte Ltd is serving Singapore's Engineering Industry in many diverse categories, such as the Water, Food, Power Generation, Marine, Offshore, Refinery, LNG Terminals and Petrochemical industries. Founding members and technical teams started primarily as Thermal Spraying Coating, Surface Engineering Experts and Mechanical Technical Specialists with very extensive knowledge and experience in the Rotating, Stationery and Mechanical Equipment. Also, WWG Engineering’s team of experienced Engineering and Manufacturing Personnel possess an extremely unique combination of experience in Manufacturing, Mechanical, Materials, Surface Science and Engineering.

With such a Unique and Specialized Technological Engineering background, WWG Engineering Pte Ltd provides Integrated, Complete One-Stop Engineering Services and Solutions, with presences in Singapore, Kuala Lumpur, Johor, Terengganu, and Sarawak Engineering Plants. Already, WWG Engineering is making its mark as a Regional Industrial Leader in the areas of Engineering Equipment and Components Refurbishment, Rebuilding, Repairing and Re-manufacturing.

WWG Engineering Solution provide many Engineering Services

WWG Engineering Solution provide many Engineering Services

Thermal Spray Coating

WWG Engineering’s Core Competency consists of a series of Surface Modification Technologies. A...

Cold Spray Technology

Early years of Cold Spray development within WWG Engineering has been very much "market driven&...

Anti-Corrosion / Protective Coating

Corrosion resistant coatings protect metal components against degradation due to moisture, saltspray...

Welding Technology

It was reported that, there was archaeological evidence of early Egyptian welding dates back as far ...

Hard Chrome Plating

WWG Engineering offer the hard chrome services, with facility and plating tanks capable of accepting...

Metal Machining & Cylindrical Grinding

Machining Workshop at the WWG Engineering was set up with very specific objectives: to manufactu...

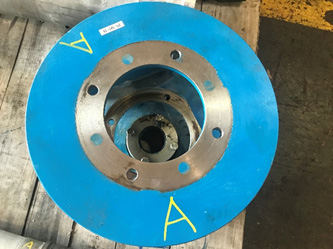

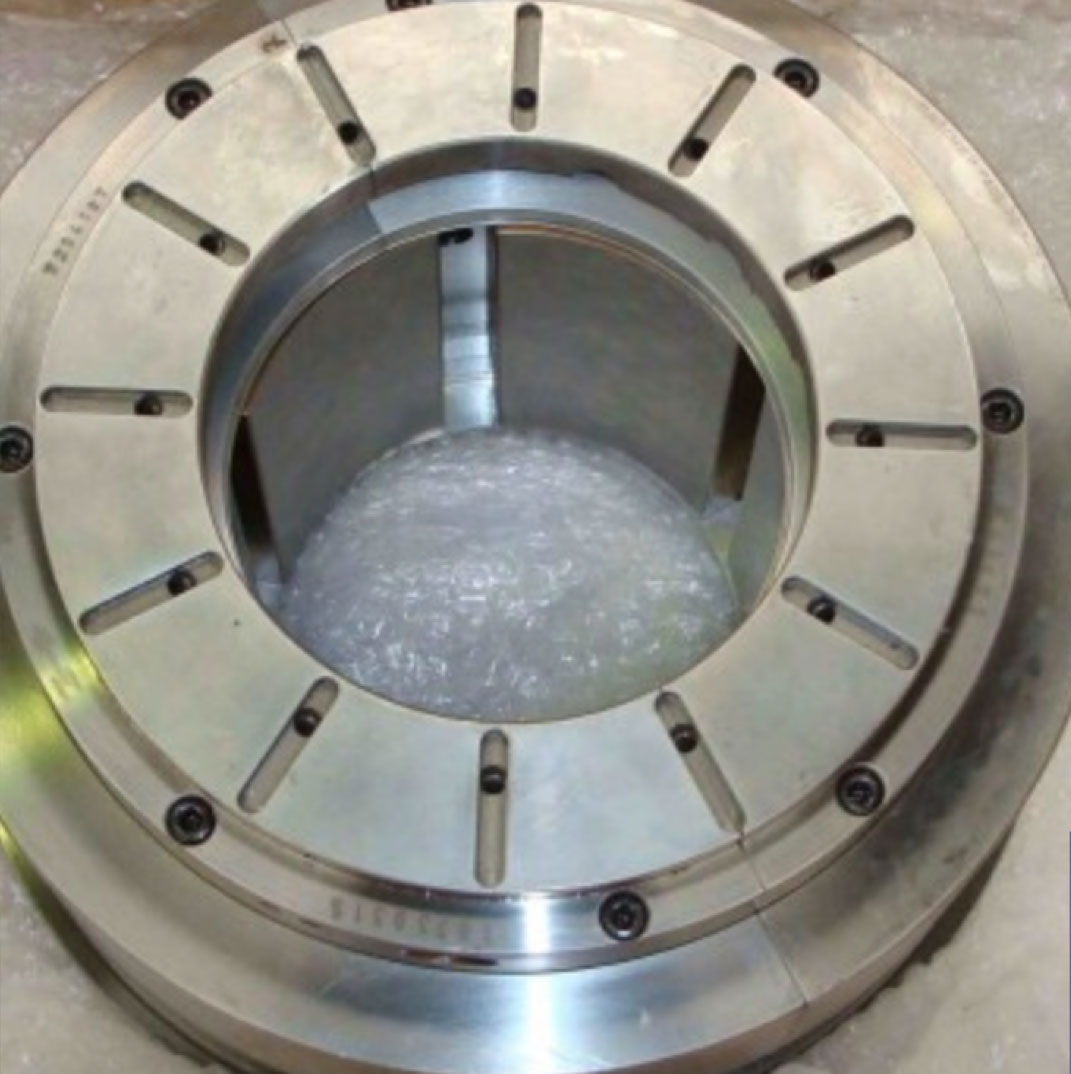

White Metal Bearings

In WWG Engineering, Babbitt White Metal deposition methods are : Thermal(Metal) Spraying, La...

Hydraulic Cylinders

Hydraulic Cylinder was invented 4 century ago by Blaise Pascal (1623-1662), in the 17th century. P...

Dynamic Balancing

Dynamic Balancing is part of WWG Engineering's complementary services. In WWG Engi...

Process Piping

About WWG Engineering “Process Piping Department” When we talk about Process Piping in ...

Gear Fabrication

Introduction WWG Engineering Pte Ltd is part of a diversified Business and Engineering Group of C...

Carbon Graphite Bushing

Carbon Graphite Bushing We are providing High Grade Carbon Graphite Bushing, primarily adopting S...

Laser Cladding

UHLATM – WWG’s Ultra High-Speed Laser Application The Birth of Ultra High-Speed Low-Tem...

On-Site & In-Situ Machining

In WWG Engineering's unique business formulation, all processes and technologies in the workshop...

Electrical, Electronics & Instrumentation Services

At WWG Engineering Pte Ltd, we pride ourselves as Singapore’s trusted specialists in Electrica...

Laser Alignment Technology

WWG’s laser Alignment Development: In WWG Engineering Pte Ltd, we deploy very high precisio...

News & Events

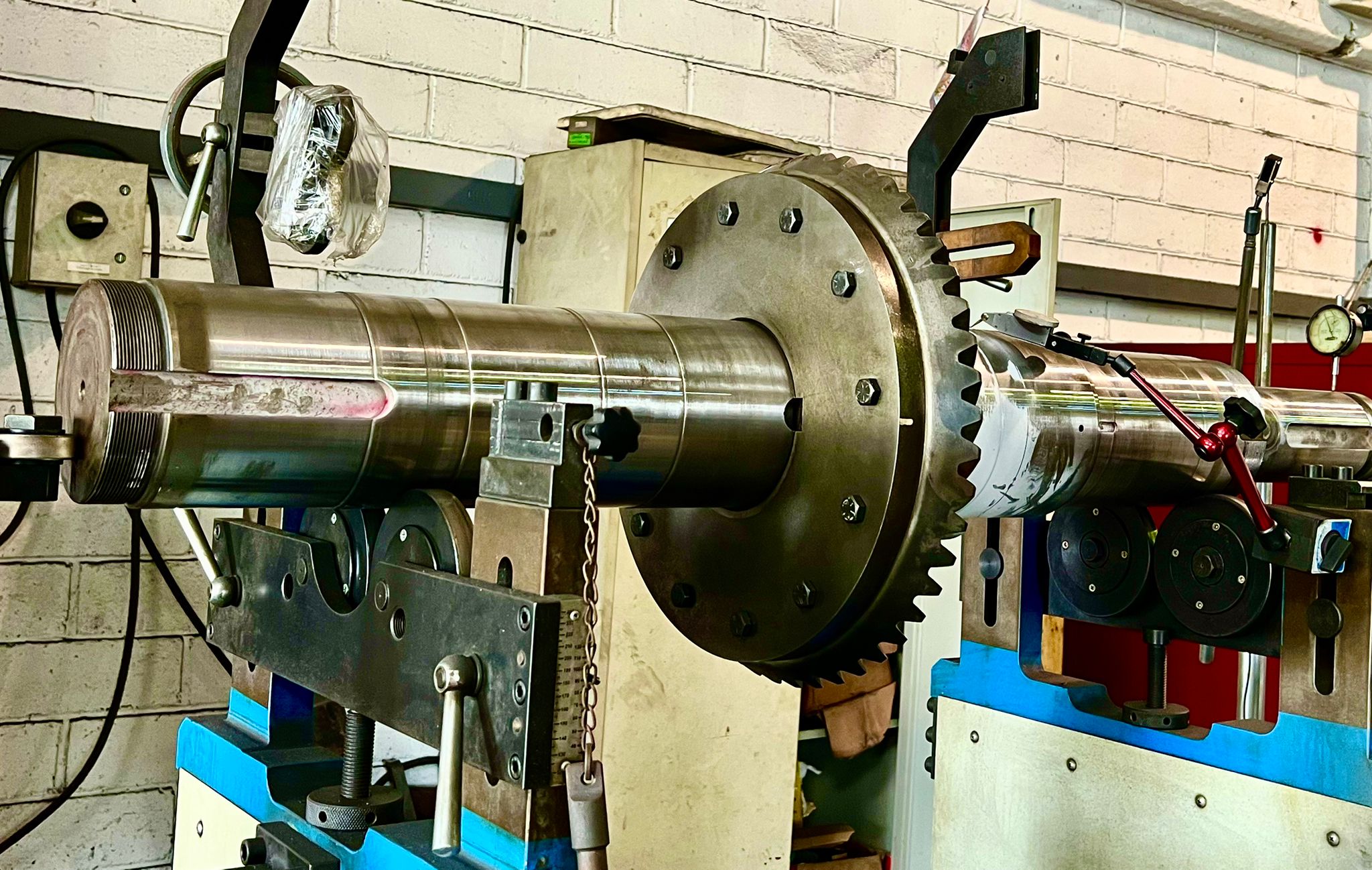

Precision Grinding of Large Main Engine Crankshaft

Date : January 24, 2026WWG Grinding Workshop is the largest of its kind in Singapore. Besides a mid size surface grinding, ...

+

WWG In-Situ - Metal Stitching on Main Engine Block

Date : December 31, 2025Great success for WWG In-Situ work, performing Metal Stitching repair work at a Manjung Shipyar...

+

More Electrical Works On-Board Vessels

Date : December 29, 2025WWG Engineering's latest Business Division is "Electrical, Electronic and Instrumentation&q...

+