Phone : +65 6861 0960 Email : sales@wwgengineering.com

FEED-WATER PREHEATER PUMP OVERHAULING REPORTBack

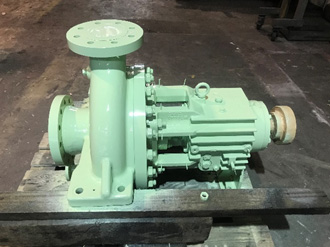

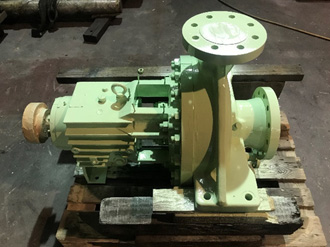

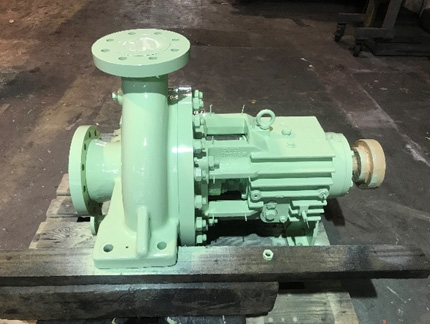

WWG Engineering has worked with Sembcorp to overhaul their feed-water preheater Apollo pump.

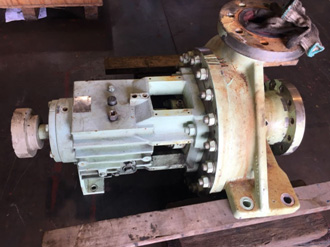

1-A) INCOMING CONDITION & DISMANTLING

The process began with the dismantling of parts followed by a dimension and run out check. A bore check is done on the impeller and a dimension check is done on the wear ring. Masking and blasting is then carried out, as well as coating.

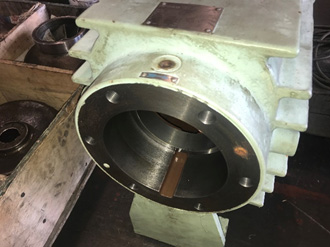

2-A). MASKING & BLASTING

To complete the task, a combination of techniques such as blasting, welding and machining were carried out by our team on the top sheaves.

2-B). PRIMER COATING (ONLY FOR EXTERNAL PAINTING

To complete the task, a combination of techniques such as blasting, welding and machining were carried out by our team on the top sheaves.

2-D). INTERNAL COATING USING CERAMIC POLYMER CN200

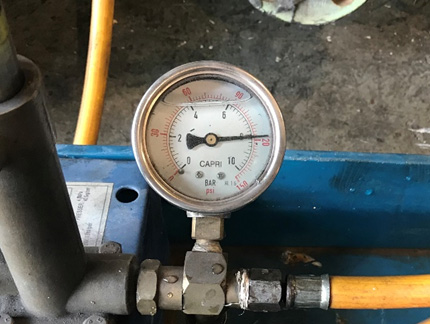

Finally, the reassembly is done with new consumables, ending with a pressure test.