Services Back

Hydraulic Cylinders

Hydraulic Cylinder was invented 4 century ago by Blaise Pascal (1623-1662), in the 17th century. Pascal was a French mathematician. He studied fluids, pressures and vacuums in the mid-1600s.

Nearly 100 years later, in 1738, Daniel Bernoulli put Pascal's fluid power discovery to use by pressurizing water in pumps and mills using Bernoulli's principle. In 1795, the first hydraulic press was patented by Joseph

Hydraulic Cylinders

Hydraulic Cylinder was invented 4 century ago by Blaise Pascal (1623-1662), in the 17th century. Pascal was a French mathematician. He studied fluids, pressures and vacuums in the mid-1600s.

Nearly 100 years later, in 1738, Daniel Bernoulli put Pascal's fluid power discovery to use by pressurizing water in pumps and mills using Bernoulli's principle. In 1795, the first hydraulic press was patented by Joseph Bramah in England, a crucial impetus towards industrial revolution.

About Hydraulic Cylinder

Hydraulic systems are the key technology behind many industrial machinery developments and inventions. The science principal of hydraulics is in such a way that when you apply pressure at one given point, energy will be transmitted to another point via an incompressible fluid, in this case is generally a hydraulic oil.

Hydraulic cylinder is a very valuable and inseparable part of modern civilisation. From lifestyle tools to industrial equipment, from daily-life mechanical facilities to heavy engineering machineries, there are unlimited hydraulic cylinder applications that go beyond your imaginations.

Hydraulic Cylinders are Used in What Industry?

Hydraulic Cylinders are used in dozens of industries that we know of. Some examples are:

- Oil and Gas

- Petrochemical and Refineries

- Power Generation Plants

- Marine Vessels

- Automotive

- Aerospace

- Engineering Manufacturing Facility

- Landscaping

- Agriculture Equipment

- Construction

- Entertainment Industry

- Personal Fitness Industry

Where Hydraulic Cylinders Used

There are hundreds of thousands of physical applications. Here are some examples…

- hydraulic presses, cranes, forges, and packing machines

- agricultural machines, construction vehicles, trucks, tractors, bulldozers, lawnmowers, backhoes, dump trucks, skid loaders, and tree chipper

- industrial and construction hammers, pullers, punches, clutches and brakes.

- marine equipment, cranes, aircraft control surfaces and landing gear, ships and large watercraft, offshore drilling and mining equipment, and various types of machinery.

- Airport, seaport, transportation terminals, wharfs infrastructure machineries, waterway barrage gates.

- hydroelectric power, other industrial power generation plants machineries and energy production applications.

- robotic arms, presses, lathes and many machine shops machineries

Hydraulic equipment operates with the help of a vast range of valves, pumps, filters and actuators.

Basic Principal of Hydraulic Cylinder

Hydraulic cylinder is designed and constructed to operate under high pressure, high wear and tear harsh operating conditions. In certain applications, hydraulic cylinder suffered from corrosions. In design, material selection is crucial. Critical component surface finishing and fitting tolerances are in high precision. Basically, hydraulic cylinder is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke.

Hydraulic cylinders generate power output from pressurized hydraulic fluid. The science principal of hydraulics is in such a way that when pressure is applied at one given point, energy will be transmitted to another point via an incompressible fluid, in this case is generally a hydraulic oil.

A large part of hydraulic cylinder is the cylinder barrel, whereby a piston head connected to a piston rod moves back and forth. The barrel is closed on one end by the cylinder cap and the other end by the cylinder head or gland. The piston has sliding rings and seals. The piston divides the inside of the cylinder into two chambers, the bottom chamber and the piston rod side chamber.

Single-acting vs. Double-acting

Single-acting Hydraulic Cylinder:

- design is simpler

- more economical to build

- hydraulic fluid enters through a port at one end

- rod extension via area differential

- by external force, internal retraction spring or gravity returns the piston.

Double-acting Hydraulic Cylinders:

- there is a port at each end or side of the piston

- supplied with hydraulic fluid for both retraction and extension

Main Components

These are key components of hydraulic cylinders:

- Cylinder base connection

- Cylinder barrel

- Cylinder base or cap

- Cylinder head

- Piston rod

- Seal gland

- Seals

Other parts

There are many component parts that make up the internal portion of a hydraulic cylinder. All of these pieces combine to create a fully functioning component.

- Cushions

- Internal Threaded Ductile Heads

- Head Glands

- Polypak Pistons

- Cylinder Head Caps

- Butt Plates

- Eye Brackets/Clevis Brackets

- MP Detachable Mounts

- Rod Eyes/Rod Clevis

- Pivot Pins

- Spherical Ball Bushings

- Spherical Rod Eye

- Alignment Coupler

- Ports and Fittings

Singapore Hydraulic Cylinder Specialist – WWG Engineering

As a Singapore Surface Modification Technology Specialist, WWG Engineering core specialization is in Thermal Spray Coating, Chrome Plating, Surface treatments, Workshop Machining and Mechanical Fitting works. These combined capabilities had always allowed WWG Engineering to explore new engineering opportunities, in terms of products and services.

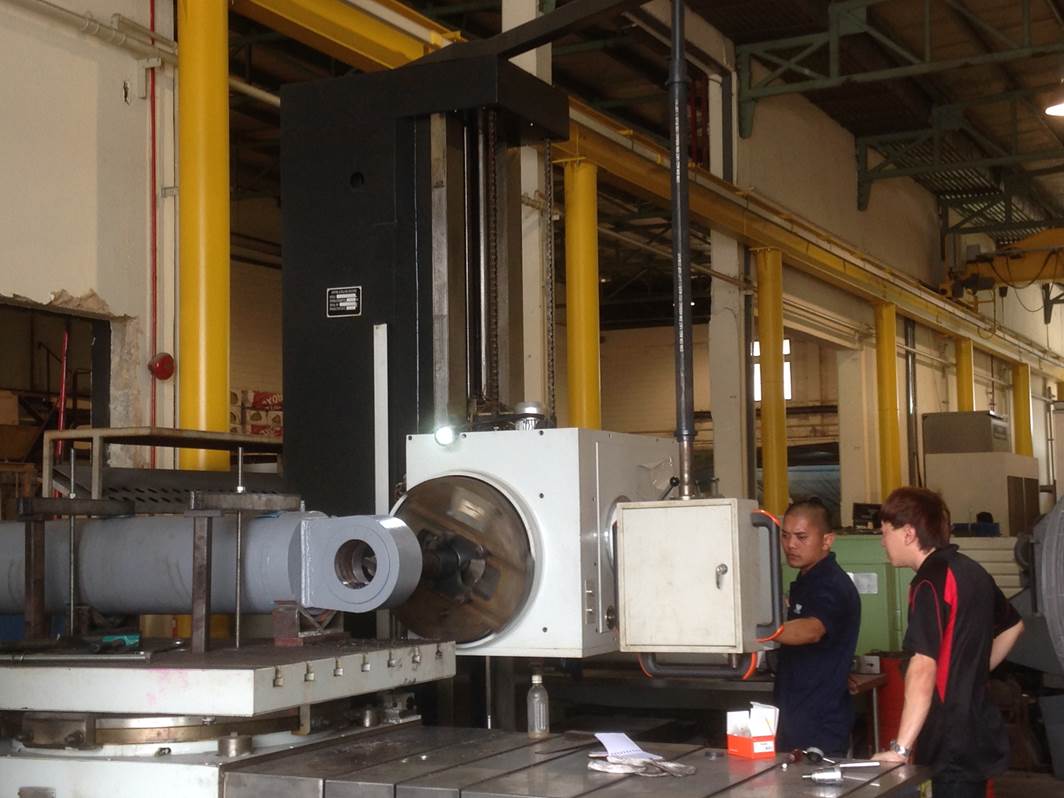

Hydraulic Cylinder Business Division in WWG Engineering, was established in 2014. Setting up by a team of knowledgeable, experienced Marine and Offshore Hydraulics System Specialists, the Team was strong in hydraulics knowledge and mechanical fitting works. Whereas WWG Engineering offered excellent complement on hydraulic cylinder assembly such as thermal spray coating or chromium plating on piston rod, grit-blasting, anti-corrosion coating of exterior, welding repair on body damages etc., complete pressure and leak testing etc.

The good synergy and excellent combination of strength from Hydraulic Cylinder Specialists Team have offered WWG Engineering a complete technology that was superior for both Repair, Refurbishment and Re-manufacturing of hydraulic cylinders, serving the Oil & Gas, Marine and the Construction industries.

Repair and Refurbishment of Hydraulic Cylinder

WWG Engineering work scope is very much depending on customer requirements and expectations. In general, it is as follow:

- Removal from site

- Complete degreasing, cleaning up

- Disassemble full assembly

- Full inspection

- Identify all faulty, damaged parts

- Dimensional Calibration

- Photographic record

- Create drawing record

- Surface reclamation, repair recoating, re-plating and finishing work

- Full barrel, rods refurbishment with large format workshop machineries

- Cylinder barrel exterior TSA anti-corrosion coating

- Cylinder barrel exterior epoxy coating protection

- NDT, MPI, dimensional and overall work report

- Spare parts replacements with new supply

- Re-assembly with full accessories

- Pressure testing

- Proper packing and delivery

Re-Manufacturing of Hydraulic Cylinder

WWG Engineering work scope is very much depending on customer requirements and expectations. In general, it is as follow:

- Secure customer’s specifications

- Establish engineering drawing

- Customer approval on drawing and specification

- Material procurement for manufacturing

- Full spare parts requirement

- Cylinder barrel vessel design

- Cylinder rod design

- Complete machining/grinding/honing work

- Final dimensional calibration

- Apply necessary coating, plating work

- Apply necessary anti-corrosion work, epoxy coating work

- Cylinder Assembly

- Final inspection

- Pressure testing

- Packing and delivery